This is a “coaxial collinear” based on the design from John, VK2ZOI (see http://vk2zoi.com/articles/dual-band-high-gain-flower-pot/). See the original article for more details.

The antenna is constructed from RG58/U coax, 22mm plastic plumbing (waste) pipe and aluminium cooking foil. It’s simple and cheap to construct, and seems to have fair performance. Unfortunately it needs some “original thinking” on the mechanical perspective, but that’s probably quite easily fixed.

Electrically, the antenna consists of two half wave elements at 2m stacked one above the other; a piece of coax in the middle inserts a half wavelength phase shift to make the second half radiate effectively. At 70cm each radiating element is one-and-a-half wavelengths, and a foil “outer” makes the whole behave as four stacked half wavelengths. There are two possible explanations as to how all of this works, of which I prefer the second:

- Because all of the elements produce a solution to the electromagnetic field equations at the correct centre frequencies;

- “It just does”.

John describes the antenna as a prototype, unproven design. I constructed the first version exactly as described, and found that it operated on both bands but wasn’t ideally matched on either (with VSWR ~2.2 on 2m; I can’t measure calibrated VSWR on 70cm). It also appeared, using an antenna analyser, that it was trying to resonate on two different frequencies.

Could I do better? I checked all the element lengths using a simple spreadsheet, using 95% velocity factor for wire and 66% for RG58/U coax. That suggested the antenna was nearly 20cm too short – enough to make a difference. I remade the antenna and found its VSWR was excellent – dipping to perhaps 1.2 on 2m and “no bars shown” on the FT817 on 70cm. That’s as good as you are likely to get on a collinear without a lot more work.

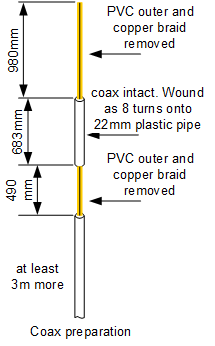

The antenna is made from a piece of RG58/U coax. Mine was made with cable from Nevada Radio; other brands may have slightly different velocity factor and need different lengths. You will need at least 5m of coax to begin!

The dimensions shown are for the mark 2, “correct” lengths.

It requires the PVC outer and braid removing from the coax in two places, leaving the PTFE centre insulator intact. Use a sharp knife to remove the outer, then side cutters to “nip” the braid until freed at both ends; it can then be bunched up and slid off. I used heatshrink sleeving to seal the joins.

Keep the removed braid for the next heavy duty earth strap you need!

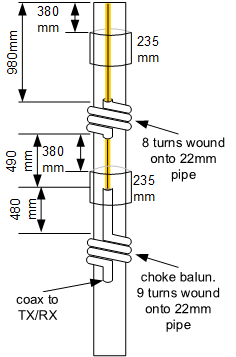

The coax is “assembled” on a 2.5m piece of 22mm plastic waste pipe. In two places the coax is close wound onto the outside of the pipe; it then threads inside the pipe for the intermediate sections. Some careful work with a 6.5mm drill and a pair of tweezers will pay off here!

Finally two pieces of aluminium cooking foil are glued / taped onto the outside of the tube in the positions shown. They are each 235mm long. In principle they can be slid up or down to optimise VSWR, but I found that only gross changes made any difference.

The foil will need to be protected, and the holes into the pipe need to be sealed. You can get heat shrink sleeving big enough to do that, but it is getting pricey (it will comfortably double the cost). Alternatively use carefully wound self amalgamating tape over the two chokes and the foil.

The “middle” piece of coax that is wound onto the pipe is a phasing section. The bottom section is a choke balun: above it the coax outer deliberately radiates, while below the choke it acts as a normal coax feeder. You can test whether it has been effective by holding the coax near the TX end and seeing if the VSWR changes. Only do this at low power though!

Electrically, my mark 2 version works well. Where it fails is in mechanical design: it is around 2.2m long and the PVC plumbing pipe is just too flexible. I’d like it if the antenna lasts longer than a day, but put up on a roof in a breeze it might not make that!

A credible structure might be possible using one of the telescopic fibreglass “roach pole” type fishing rods. A posh carbon fibre one would be no good (it would be conductive) but fibreglass ones are readily available. I’m not sure if they retain strength if drilled; some reinforcing may be needed.

I’ve moved on to other projects for the moment, so it will be a while before I do any more with this. Does anyone else want to pick up the cudgels and have a go at finishing this?